SolarCool Technology considerably increased the efficiency of the refrigeration at the large bakery headquarters of Golden Harvest in Malta, in partnership with Angelo Aquilina Ltd. Our product is an innovative, combined technology designed to harvest the free energy from the sun, thus creating thermal energy to better assist the refrigerant compression process.

Customer Situation

Refrigeration installation and repair service providing tailormade products and services for various commercial applications with a focus on energy efficiency and environmentally sound products.

Solution

Establishing a partnership between SolarCool and Angelo Aquilina Ltd. Ascertain SolarCool’s energy saving credentials through installations at one of the company’s long term clients, Golden Harvest.

Benefits

- Reduced electricity overheads

- Reduced ongoing equipment maintenance costs

- Extended equipment lifespan

- Reduced CO2 production

Case Study

Founded in 1998, Angelo Aquilina Refrigeration Supplies Ltd. established a refrigeration installation and repair service based on the island of Malta. In partnership with a well-respected overseas company, the company design & develop their own refrigeration systems, from split units through to multi-stage compression systems for all areas within the food industry. Examples include supermarkets, storage and food processing sectors.

Continually keeping ahead of consumer concerns, Angelo Aquilina Refrigeration Supplies Ltd is also proud to offer highly energy-efficient refrigeration systems. This allows businesses to reduce their energy consumption.

On first introduction of our partnership with Angelo Aquilina Ltd. our first job was to demonstrate our energy saving credentials. This was undertaken through installing our innovative product at one of their long term large clients.

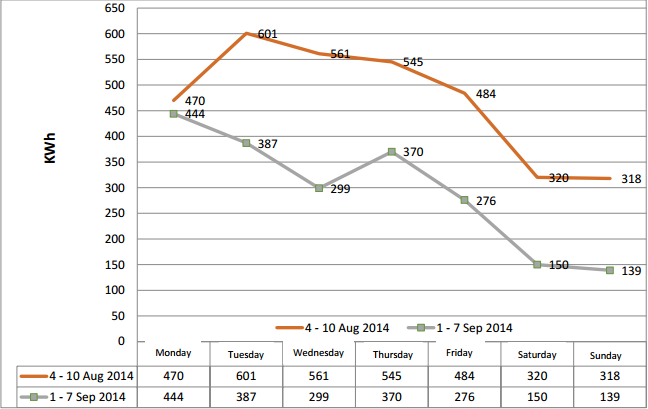

The test site encountered zero cloud cover throughout the whole period of the test, which is not unusual for this part of the world during the month of August.

- External ambient temperatures were c.33°C

- Plant Room ambient temperatures were c.31°C

- Process Cooling required temperatures were16°C

Actual energy consumption savings throughout sunlight hours averaged 53%.

If you’d like to know more about this project, download their case study sheet o visit solarcoolenergy.com